Today we’d like to introduce you to John Nelson.

Hi John, please kick things off for us with an introduction to yourself and your story.

I have over two decades of experience in industrial maintenance and engineering. Raising a family of five was challenging, especially with the frequent late-night calls when plants were shut down due to equipment failures. For years, I said there had to be a better way to get technicians the data and support they need right at the machine. The first time I saw a QR code, I knew it was the ideal solution.

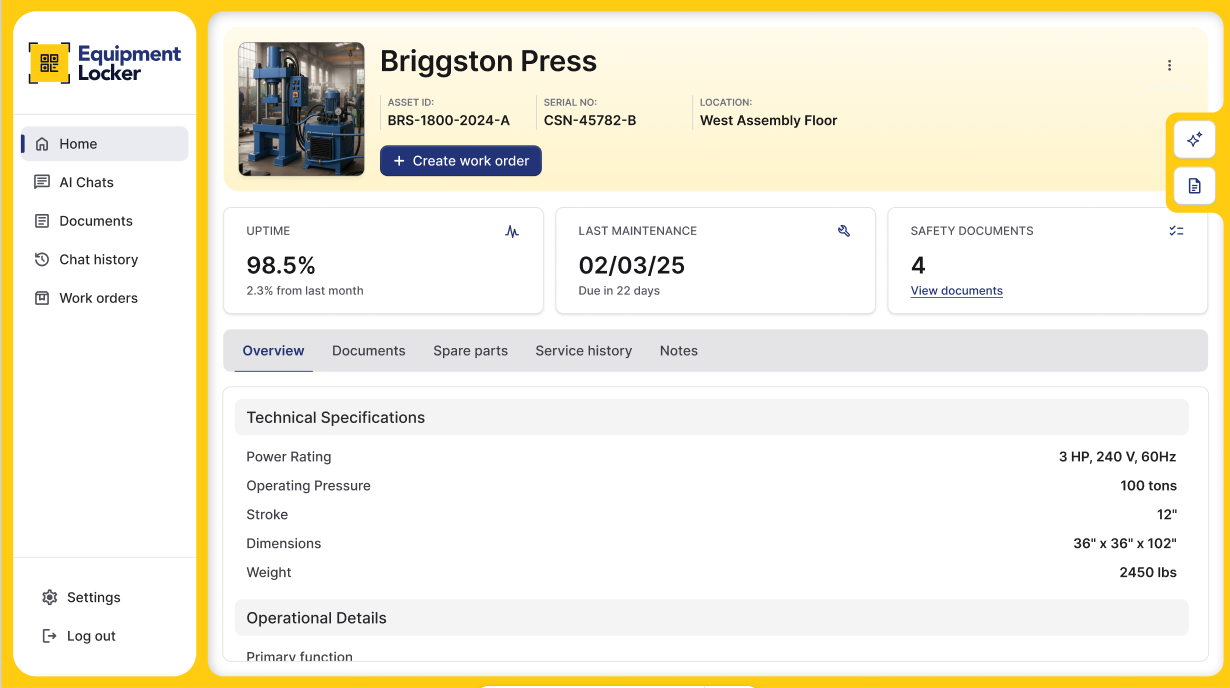

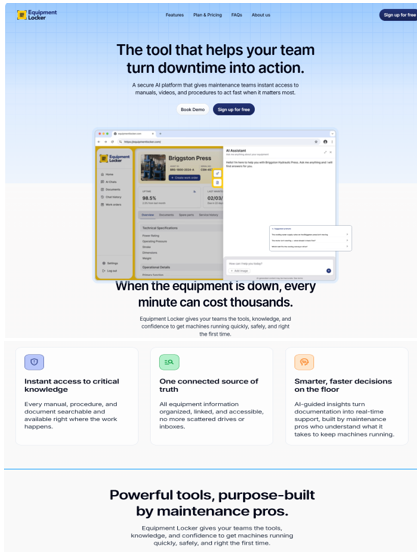

The software I’m developing uses QR codes to take a technician directly to all the information for the specific machine or device they’re working on. All the drawings, procedures, programs, and parts are instantly accessible. With AI integrated, they can query anything related to the issue to help diagnose and repair the problem quickly and safely.

Can you talk to us a bit about the challenges and lessons you’ve learned along the way. Looking back would you say it’s been easy or smooth in retrospect?

I have obligations to my current employer, and I’m careful to ensure my side venture never interferes with those responsibilities. Naturally, a startup brings funding, timing, and countless other pressures that weigh on you. As a solopreneur, you end up wearing a lot of hats.

Can you tell our readers more about what you do and what you think sets you apart from others?

I’m an industrial maintenance and engineering professional with over two decades of hands-on experience across multiple manufacturing sectors. I specialize in diagnosing complex mechanical, electrical, and PLC issues under pressure, and I’m the person people call when the plant is down.

What sets me apart is the combination of deep field experience in both electrical and mechanical systems and the ability to break down complicated problems to identify true root causes. I’m passionate about eliminating recurring failures and building systems that are safer and more reliable.

I’m most proud of two things: consistently getting production back online safely, and channeling that experience into building Equipment Locker, a platform designed to eliminate the wasted time technicians spend hunting for scattered manuals, drawings, and programs, while also helping bridge gaps in experience on the plant floor.

Do you have any advice for those just starting out?

Don’t hesitate to explore new ideas. Test out your concepts before committing funds. Networking is critical, you can not possibly know all that is required for a startup. Going back to my original point, don’t hesitate. I let this concept churn for almost a decade without pursuing it.

Contact Info:

- Website: https://www.equipmentlocker.com

- LinkedIn: https://www.linkedin.com/in/john-nelson-b8204b26/

- Other: https://www.intentiveindustrial.com/